New Orleans Pump Stations

Challenge

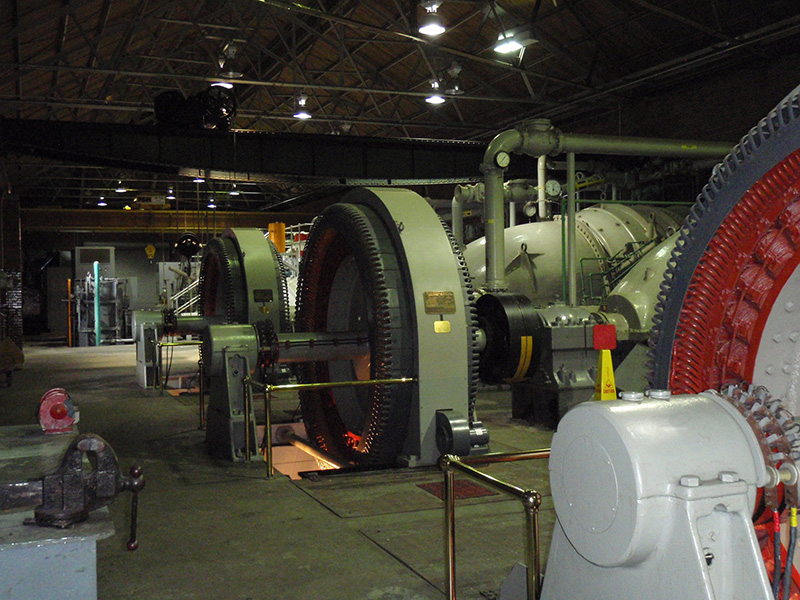

Critical to pump water and minimize flooding, the early 20th century drainage pump stations in New Orleans were not designed to withstand hurricane-force winds, and Hurricane Katrina left most of the stations submerged. The city needed to determine the post-Katrina condition of the pump stations and repair the historic masonry buildings, as well as protect them against future storms.

Solution

Working with Masonry Solutions International, Atkinson-Noland & Associates conducted an extensive condition survey of the existing masonry buildings. In situ material testing, including surface-penetrating radar (SPR) and flatjack testing, determined material properties and assessed water penetration resistance. Following the initial analysis, we provided construction engineering services to strengthen the buildings using historically appropriate techniques. We helped the contractor design a reverse-tapered anchorage that provided internal vertical reinforcement with a very short stainless-steel bar. In addition, we helped develop hollow stainless-steel rods to provide reinforcement and facilitate installation of compatible injection fill (CIF), a specialized grout. This custom solution eliminated the need for a plastic injection tube adjacent to the rod.

Solutions Provided

A fiber-optic borescope is inserted in small holes drilled into mortar joints to evaluate internal wall conditions. Borescope investigations provide detailed information about internal wall features discovered through nondestructive evaluation. These surveys can also evaluate corrosion of embedded metals and continuity of brick header courses. Borescope analysis can reduce or eliminate the need for destructive probe openings.

Compatible injection fill (CIF) is customized to the material properties of the host structure, based on nondestructive evaluation and materials characteristics testing. Technicians pump a fluid, cement-based grout mixture into cracks, voids, or cavities within masonry. Low injection pressures prevent damage, while strengthening already fragile materials.

A visual condition survey locates and identifies areas of damage and deterioration. Dilapidation, cracks, signs of movement, and other localized failures are mapped and documented on drawings to help determine scope of required repair work. Significant structural cracks are measured for size, location and directionality, where accessible. In addition, sources of deterioration and likely causes of damage are identified, along with repair recommendations, as applicable.

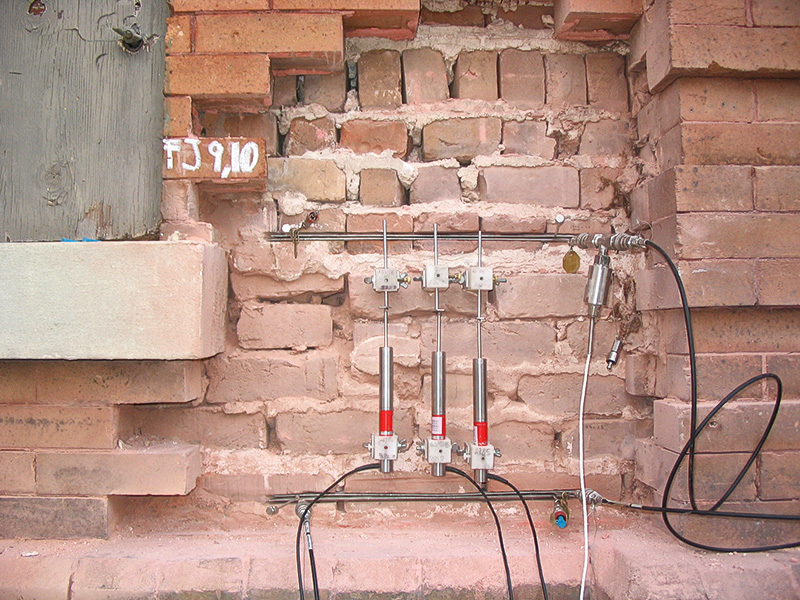

A flatjack is a flexible steel envelope, thin enough to fit within a masonry mortar joint. During testing, the flatjack is hydraulically pressurized and applies stress to the surrounding masonry. Flatjack tests can determine engineering properties of older and historic structures for structural evaluation, including in situ stress (ASTM C1196), masonry compressive modulus (ASTM C1197), masonry compressive strength (ASTM C1197), and mortar shear strength (ASTM C1531).

We use an in-house laboratory for testing historic and modern masonry material properties. Work performed includes characterization of brick, block, and stone properties; mortar analysis; anchor strength; and grout development, following standard test methods developed by ASTM, ACI, the State of California, and others.

Nondestructive tools such as moisture meters, surface-penetrating radar, and infrared thermography can identify areas of high moisture content and track moisture penetration back to its source. Spray tests are often used to identify moisture leakage pathways and the rate of moisture infiltration. ANA can perform tests in accordance with ASTM C1601, ASTM C1715, ASTM E514, ASTM E1105 and AAMA 501.2.

Structural analysis characterizes the structural response when subjected to a variety of conditions and actions, such as changing environmental conditions, new load requirements, etc. This assessment involves evaluating a structure under stress, deformation and displacements, and reactions. Nonlinear analysis through finite element (FE) modeling can be used to pinpoint the source of excessive stress leading to damage of the structure (e.g., cracking in tension, crushing in compression) when evaluated under service and ultimate load ranges.

ANA can recommend appropriate repair techniques for a variety of structures, from modern commercial and industrial structures to protected historical monuments. Structural repair services extend from initial assessment to development of rehabilitation schemes, on-site observation, and quality control of repair measures.

Surface-penetrating radar (SPR), also referred to as ground-penetrating radar or impulse radar, provides valuable information about structural and non-structural building components without causing damage. The radar data reveals voids, construction layers, and the presence of other materials, such as metal inclusions, as well as the thickness of the element.

Result

These historic buildings were strengthened using helical ties to connect wythes with vertical and horizontal stainless-steel enhancement bars, internally installed. We also designed CIFs to match the material properties of the existing masonry. Hollow reinforcement rods permitted grout injection from the bottom up, which stabilized the walls and bonded new reinforcement to the surrounding masonry. Today, the pump stations are not only stronger, but also more resistant to flooding.

Project

New Orleans Pump Stations

New Orleans, Louisiana

Client

U.S. Army Corps of Engineers

New Orleans, Louisiana

Partner

Masonry Solutions International