New Construction Challenge: Concrete Defects

Challenge

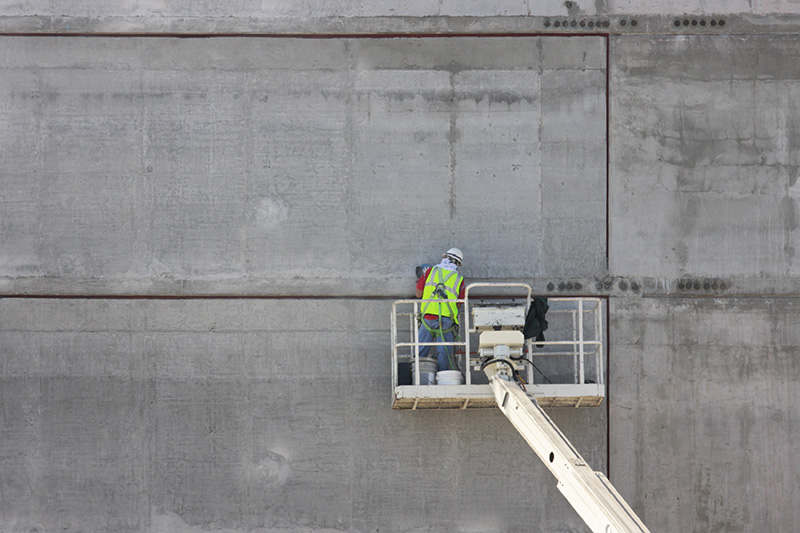

The construction team for a new high-rise building in Manhattan was running into issues with the concrete frame structure. The project engineer requested Atkinson-Noland & Associates to evaluate suspected defects in the concrete construction—in part because of our expertise with nondestructive evaluation and concrete, in part because of our rapid response time.

Solution

We arrived on site two days after receiving project approval. First, we met with the project engineer and developer to understand the site conditions and the types of defects they expected to see. The range of conditions required several different testing approaches, including surface-penetrating radar, laser survey and pachometer testing. We also arranged for removal of concrete samples, which we tested in the laboratory for compressive strength.

Solutions Provided

We use an in-house laboratory for testing historic and modern masonry material properties. Work performed includes characterization of brick, block, and stone properties; mortar analysis; anchor strength; and grout development, following standard test methods developed by ASTM, ACI, the State of California, and others.

Laser levels, electronic distance meters, and high-precision altimeters map displacement of floors, walls, and ceilings. These tools provide information that is used in structural analysis or to monitor movement over time. Unanticipated movement—including leaning or bulging walls, slab settlement, and floors that are not level—can indicate critical structural issues that require remediation.

A pachometer is a specialized metal detector that locates embedded reinforcement in concrete and masonry construction. Pachometer scanning is used to map location and depth of reinforcing bars, masonry veneer anchors, shelf angles, pipes and conduit, flashing, and other embedded metals.

Surface-penetrating radar (SPR), also referred to as ground-penetrating radar or impulse radar, provides valuable information about structural and non-structural building components without causing damage. The radar data reveals voids, construction layers, and the presence of other materials, such as metal inclusions, as well as the thickness of the element.

Result

Testing revealed that conditions on site were not as bad as expected, and construction continued without schedule delays. While some repairs were required, our testing minimized the need to replace existing construction, while providing the engineer with reassurance in the accuracy and quality of the project design.

Project

New Construction Challenge: Concrete Defects

New York, New York

Client

Confidential

Partner

Silman