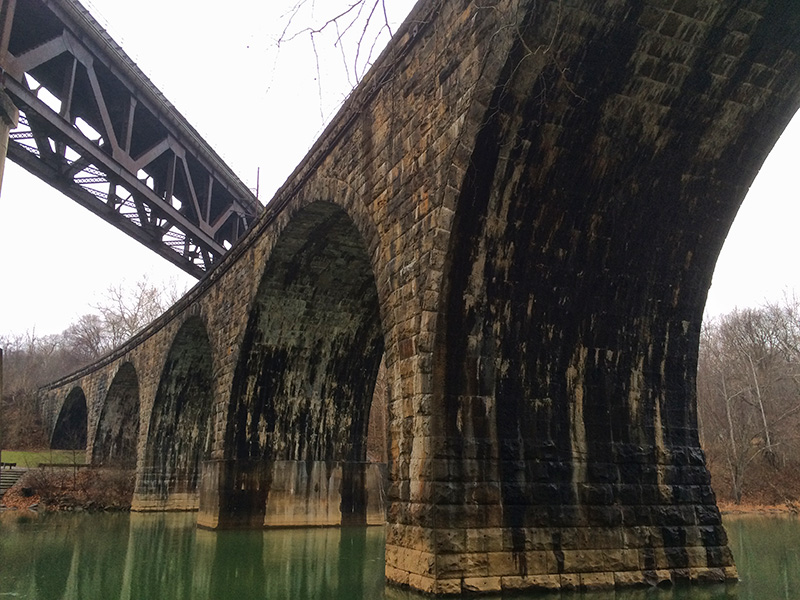

Bow Ridge Bridge

Challenge

A six-span, stone-arch railroad bridge built in 1907, the Bow Ridge Bridge was replaced by a new, steel-truss bridge when the railroad was realigned. The most recent bridge inspection found the stone arches in poor condition, with extensive cracking in all six arch barrels. The client wanted to understand how the cracks affected the bridge’s structural capacity.

Solution

Atkinson-Noland & Associates used an aerial under-bridge inspection vehicle to document the location and dimension of all significant cracks in the arch barrels. Then, surface-penetrating radar (SPR) allowed us to determine arch thickness and to evaluate arch barrels for voids. We then created a three-dimensional, finite element (FE) model of the bridge, including the existing cracks, which was used for the analysis and subsequent load rating.

Solutions Provided

We use nondestructive techniques to determine “as-built” conditions for rating bridges. Then, working with BDI engineers, we load-test bridges to obtain deflection and strain data for calibration and verification of finite element (FE) models. Advanced FE capabilities allow us to implement complex 3D models of arch bridges and to produce accurate load ratings in accordance with current AASHTO provisions.

A visual condition survey locates and identifies areas of damage and deterioration. Dilapidation, cracks, signs of movement, and other localized failures are mapped and documented on drawings to help determine scope of required repair work. Significant structural cracks are measured for size, location and directionality, where accessible. In addition, sources of deterioration and likely causes of damage are identified, along with repair recommendations, as applicable.

This advanced computational analysis technique aids in evaluation of structural behavior, based on accurate numerical simulation of the structural response under load. By adopting reasonable modeling strategies and material properties of the actual structure (as determined through nondestructive investigation and evaluation), finite element (FE) modeling enhances the diagnosis and understanding of damage and visual distress. FE modeling also allows for an in-depth safety evaluation of the structure, contributing to the design and validation of proposed interventions.

Structural analysis characterizes the structural response when subjected to a variety of conditions and actions, such as changing environmental conditions, new load requirements, etc. This assessment involves evaluating a structure under stress, deformation and displacements, and reactions. Nonlinear analysis through finite element (FE) modeling can be used to pinpoint the source of excessive stress leading to damage of the structure (e.g., cracking in tension, crushing in compression) when evaluated under service and ultimate load ranges.

Result

Our load rating analysis, conducted in accordance with the latest AASHTO requirements, indicated that the bridge still met the performance requirements of current building codes, even though the existing damage reduced its structural capacity. We recommended routine maintenance and selected repairs to keep the bridge operational, without incurring costly and unnecessary strengthening measures.

Project

Bow Ridge Bridge

Indiana County, Pennsylvania

Client

C&C Consulting Engineers

Allston, Massachusetts

U.S. Army Corps of Engineers

Philadelphia, Pennsylvania